Submitted by Jo Daye on Wed, 15/12/2021 - 11:52

Published in MDPI Sustainability a new open access paper from Antiopi Koronaki, Aurimas Bukauskas, Aftab Jalia, Darshil U. Shah and Michael H. Ramage from the Centre for Natural Material Innovation at the University of Cambridge, ‘Prefabricated Engineered Timber Schools in the United Kingdom Challenges and Opportunities’, assesses the opportunity for prefabricated engineered timber construction methods to help meet the demand for new school places.

By 2024 the UK Government needs to provide an additional 120,000 new school places to meet growing demand.

Given the urgency of this requirement and in order to achieve Net Zero carbon emission targets we must reassess and reconsider the method of designing and building schools so that they are sustainable. The UK Government’s Construction 2025 strategy targets a 50% reduction in emissions, a 35% reduction in costs and 50% improvement in the speed of building new schools.

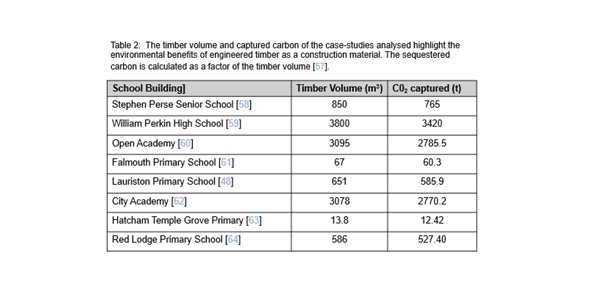

Timber consists of approximately 50% atmospheric carbon. Every ton of timber contains 1.8 tonnes of atmospheric C02. Studies show that buildings using predominately timber will sequester carbon from the atmosphere for the life-span of the building acting as a carbon-sink; offering substantial benefits as a sustainable alternative to conventional materials such as concrete and steel.

Low carbon engineered timber can be used to create flexible and adaptable spaces using platform approaches that aligned with the Construction Innovation Hub’s Platform Rulebook principles. The production of engineered timber uses a process of glueing and machine pressing layers of natural timber together which enables mass production of timber building components, whilst guaranteeing high quality and consistency in production. These components can be easily transported as modular components for assembly. In cases where the project is an extension to an existing school, the build can be completed offsite minimising disruption to pupils.

Offsite manufacture of engineered timber “has been shown to result in faster project delivery, reduced cost, higher quality assurance, reduced exposure of building materials to adverse weather conditions, reduced waste and improved worker safety.”

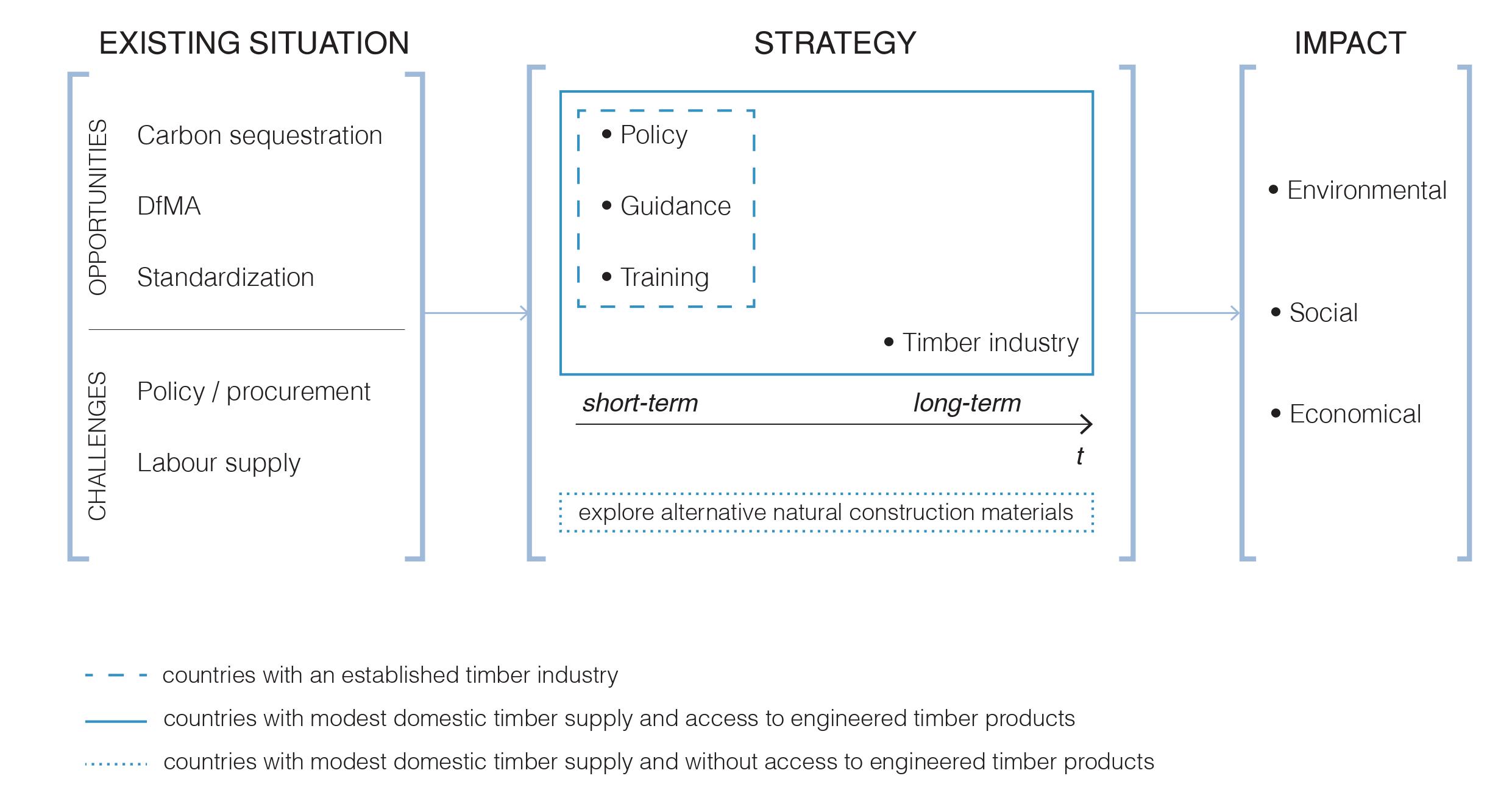

The use of prefabricated engineered timber has been successfully applied in schools and public infrastructure in a number of countries worldwide (Finland, Spain, America and Australia). There is also evidence that the use of exposed timber in school buildings facilitates greater social interaction, improved well-being and enhances the learning experience.

The paper also highlights the need to work with industry to address the shortage of skills in the construction industry and specifically for those specialist roles required for prefabricated engineered timber projects. The work concludes with an overview of the developed strategy and a method of how it can be adapted for its application in countries with different requirements and needs.

Increased use of prefabricated engineered timber to build schools has the potential to support the drive to Net Zero whilst also stimulating growth in the UK for the manufacture of timber, boosting skills and local employment and improving pupil wellbeing and learning.

This research forms part of the Centre for Digital Built Britain’s (CDBB) work at the University of Cambridge. It was enabled by the Construction Innovation Hub, of which CDBB is a core partner, and funded by UK Research and Innovation (UKRI) through the Industrial Strategy Challenge Fund (ISCF).