Submitted by Anonymous on Thu, 22/09/2022 - 16:22

Engineered timber offers a cost-effective solution to the UK’s building needs, improving construction productivity and performance. Combining digital design and off-site manufacturing, engineered-timber buildings can be efficiently and sustainably built, operated and maintained, and provide pleasant facilities for those working, living, and learning in them.

Making advances in policy and practice, CDBB researchers at the University of Cambridge’s Centre for Natural Material Innovation have demonstrated the potential for timber construction to meet demand for new primary and secondary school buildings on-time, on-budget, and within sustainability targets. The research has provided an evidence-base for policy, developed new timber-engineering solutions, and paved the way for a full-scale demonstrator: an extension to a Cambridge primary school, buildable over a summer vacation.

Big picture

In June 2020, the UK government announced a £1 billion investment in new school construction and £560 million for school repairs and upgrades as part of a package of proposals intended to stimulate the post-COVID-19 economy. The announcement highlighted the need for rebuilding projects to be “greener” to meet net zero targets. It also included a commitment to modern construction methods, recognising the high-skilled job opportunities.

Every part of the UK needs to build more schools to meet increasing numbers of pupils, while local authorities face mounting financial strain. The School Places Challenge report (2019) stated: ‘There will be 385,031 more school-age pupils in the UK by 2021/22, which equates to 12,835 additional primary and secondary school classrooms, the equivalent of 640 new schools’. Additional pressures emerge from the UK government’s Construction 2025 strategy which targeted a 50% reduction of emissions, a 33% reduction in costs, and a 50% improvement in the speed of new construction (UK Government, 2013).

The UK needs more school buildings to meet the rise in numbers of the school-age population. New innovations, methods and frameworks are essential to build more for less, meet government sustainability targets to support transition to net-zero greenhouse gas emissions by 2050, and deliver improved economic and social value.

Prefabricated construction has been shown to result in faster project delivery, reduced cost, higher quality assurance, reduced exposure of building materials to adverse weather conditions, reduced waste and improved worker safety and comfort. Crucially, compared to site-built methods, prefabricated construction requires fewer workers and provides healthier, safer, and more regionally-distributed construction jobs. These benefits are further enhanced when off-site construction is applied at scale, where the opportunity for design standardisation increases. This is particularly relevant in government-led programmes, where the volume of demand is high.

In addition to the benefits of prefabrication, construction with engineered timber promises better outcomes for the environment. Establishing new sustainable applications for renewable, energy-efficient and plant-based natural materials in the built environment, this research stands to improve building quality and mitigate the human impact on climate change.

The project

Led by Professor Michael Ramage, the CDBB researchers approached the need for school buildings as a case study to investigate and better understand opportunities and challenges for engineered-timber construction in the UK. Based in the Department of Architecture’s cross-disciplinary Centre for Natural Material Innovation (CNMI), the researchers brought expertise in plant sciences, biochemistry, chemistry, fluid dynamics, engineering, and architecture, and a commitment to transform building methods to achieve zero carbon emissions. Integrating design, technology, engineering and fabrication, they set out to develop a range of school designs and the digital means of fabricating them, to create a basis for manufacturing that can take design inputs from multiple architects, engineers, and contractors, and to influence policymakers and procurement to ensure the adoption of timber more broadly.

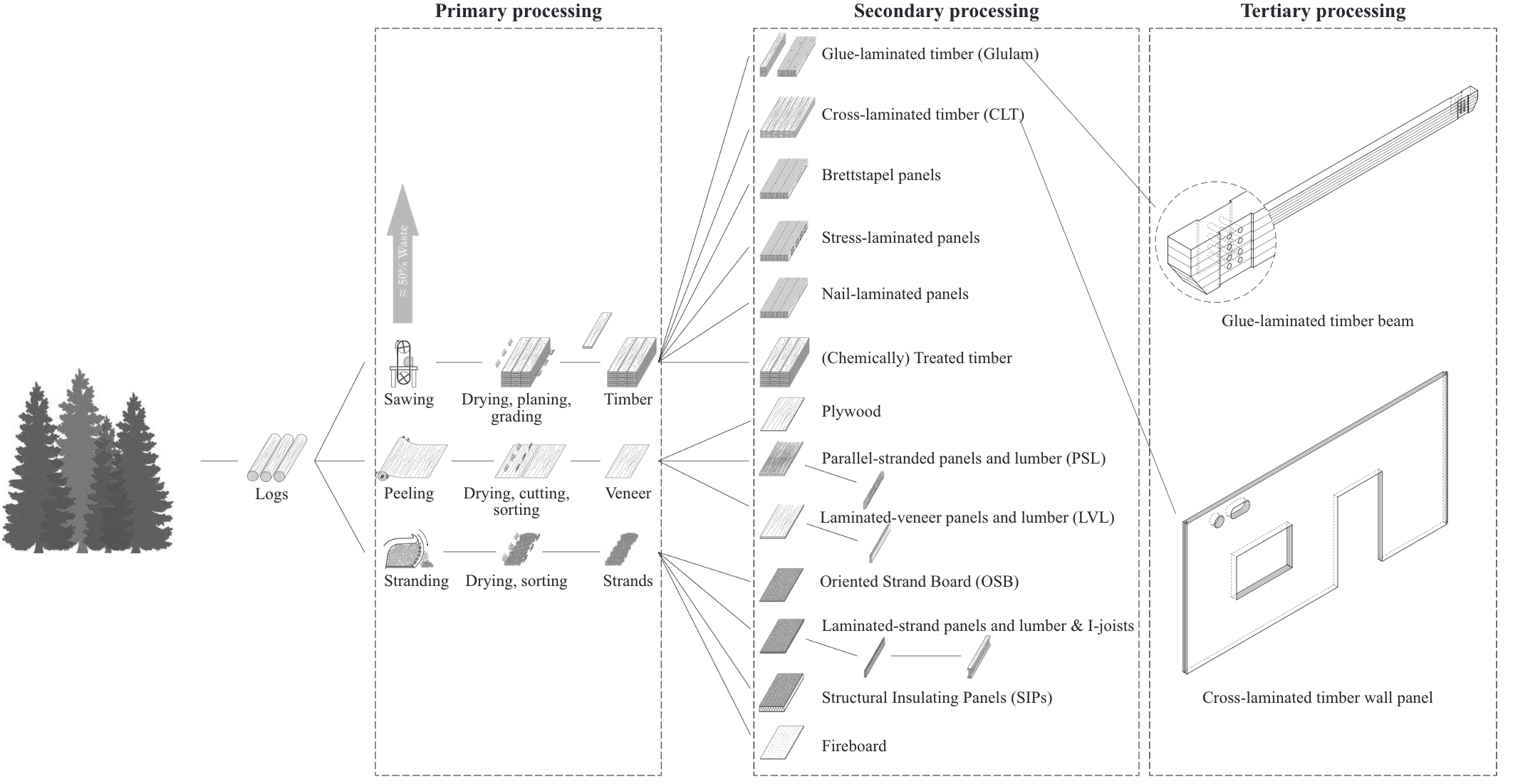

From the outset, the researchers analysed the construction process for existing engineered-timber school buildings across the UK and surveyed the legal and policy landscape, seeking to better understand opportunities and obstacles with reference to the UK context and drawing on international practice. Allied with this intellectual work, researchers also pursued technological innovation in their use of engineered materials, focusing on cross-laminated timber or CLT, a product formed out of orthogonally-stacked lumber board layers. Collaborating with industry partners, they developed a new process to weld wood and harnessed developments in digital technology to calculate efficient use of laminated timber, applying computational 3D modelling and robotic cutting and showcasing results at the London Design Biennale in 2021.

Partnering with a Cambridgeshire state school, the team ran workshops with teachers, parents and school children to design a new extension taking advantage of the many benefits of precision-engineered construction. Suitable for construction during a vacation, it is hoped this real-life demonstrator will be completed in 2023 (pending planning permission and funding decisions).

Learnings from the research have been disseminated in a range of working papers, peer-reviewed articles, conference presentations, videos and blog posts. Specific recommendations were communicated to government committees and industry bodies, including through COP26 and the UK Parliament’s Environment Audit Committee.

M. H. Ramage, H. Burridge, M. Busse-Wicher, G. Fereday, T. Reynolds, D. U. Shah,490G. Wu, L. Yu, P. Fleming, D. Densley-Tingley, J. Allwood, P. Dupree, P. Linden,O. Scherman, The wood from the trees: The use of timber in construction, Renewableand Sustainable Energy Reviews 68 (2017) 333–359

Meet the research team

Lead: Dr Michael Ramage, Director, Centre for Natural Material Innovation at the University of Cambridge

Team: Ana Gatóo, PhD candidate, Department of Architecture, University of Cambridge; Dr Aurimas Bukauskas, Dr Aftab Jalia, Dr Dario Marino, and Dr Yiping Meng, Research Associates, CNMI, University of Cambridge; Dr Antiopi Koronaki, Assistant Professor, and Dr Darshil Shah, Associate Professor, Department of Architecture, University of Cambridge

“This project provided an exciting opportunity for academic research to engage with the government on the development of guidance and policy concerning the effective, sustainable, and economical design and construction of engineered timber schools in the UK. ” -- Dr Aurimas Bukauskas

“This project presented a unique opportunity to use engineered timber in an innovative way, in line with advanced fabrication and construction methods, to design low-energy, healthy schools for our future.” -- Dr Dario Marino

Engage

Ongoing CMNI work is documented on the Centre website and social media accounts (@CamNatMat). Correspondence for the team can be addressed to natmat@aha.cam.ac.uk

Visit the project page for more on this research.

Header photo courtesy of Dr Aurimas Bukauskas