Submitted by Angela Walters on Fri, 12/04/2019 - 16:43

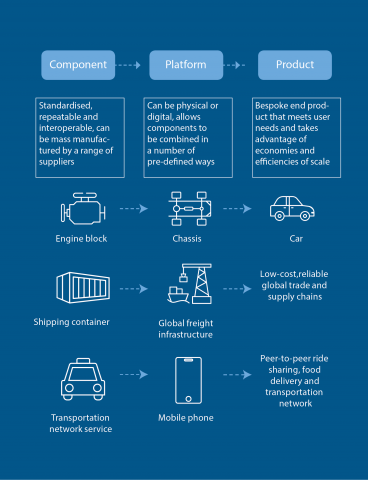

This project set out to show the benefits of a manufacture-led approach to construction, showing how it would support the commitments made by the UK government to improving the construction sector. In particular, it looked at ways in which the construction sector could learn lessons from the manufacturing, automotive and software industries and create significant value by doing so. Platforms have been critical to the development of both of these industries, allowing them to scale and innovate while reducing costs through increased efficiency.

Outcomes

This report explains how the construction sector could borrow this platform approach to design for manufacture and assembly (P-DfMA) to achieve a much more efficient and scalable approach to physical construction. Within those platforms, connections and interfaces can be standardised so that just a few designs meet a huge range of needs, and many components are repeatable. The report found that on projects for the Ministry of Justice it’s possible to construct almost all of the complex estates using a combination of just three platforms.

Method

Case Study

Next Steps

This work has been picked up by the Construction Innovation Hub.

People

Theme