Submitted by Sevcan Birdal on Wed, 18/05/2022 - 09:12

A significant proportion of the work undertaken by CDBB has focussed on the macro level, working with national and international policymakers and businesses. However, most businesses that make up the construction sector are small and medium-sized enterprises (SMEs) by definition. The priorities and key challenges that face SMEs may often be very different to those of larger organisations. So how do we ensure that everyone can benefit from increasing their digital capabilities?

The Digital Construction on a Shoestring project (initiated by the Distributed Information and Automation Laboratory at the Institute for Manufacturing and funded by Construction Innovation Hub at the University of Cambridge) sees academia and industry join forces on a collaborative programme that seeks to increase digital capabilities across all the construction sector’s SMEs and thus ensure the entire sector is able to benefit.

The Shoestring project aims to break down the barriers to digital construction by developing individual digital solutions for which the total cost of deployment is kept low. It supports incremental adoption of individual digital shoestring construction solutions which can be integrated iteratively. The solutions are designed and developed based on a simple structured procedure and deployed to companies by following step-by-step instructions. The Shoestring project differs from other digital transformation methodologies because it identifies the priority digital solutions from the start, and deploys them incrementally.

The project uses readily available off-the-shelf low-cost components (such as Raspberry Pi devices) for the development of digital construction solutions to join up suppliers with technical offices and on-site personnel. The Shoestring development methodology starts with the business prioritising its needs so the most appropriate digital construction solutions can be selected. This is followed by the creation of a more detailed requirements specification and then a solution design. The programme itself centres around the Manufacturing and Construction phase of the RIBA Plan of Work including suppliers and off-site construction SMEs, and on-site construction SMEs.

UK Construction Week, held at the beginning of May, gave the Shoestring Project Lead, Dr Gokcen Yilmaz an opportunity to share more about the project with attendees.

Dr Yilmaz informed those gathered that they conducted eight prioritisation workshops attended by 70 construction SMEs. Four of these workshops were conducted with suppliers and off-site construction SMEs, and the other four workshops were conducted with on-site construction SMEs.

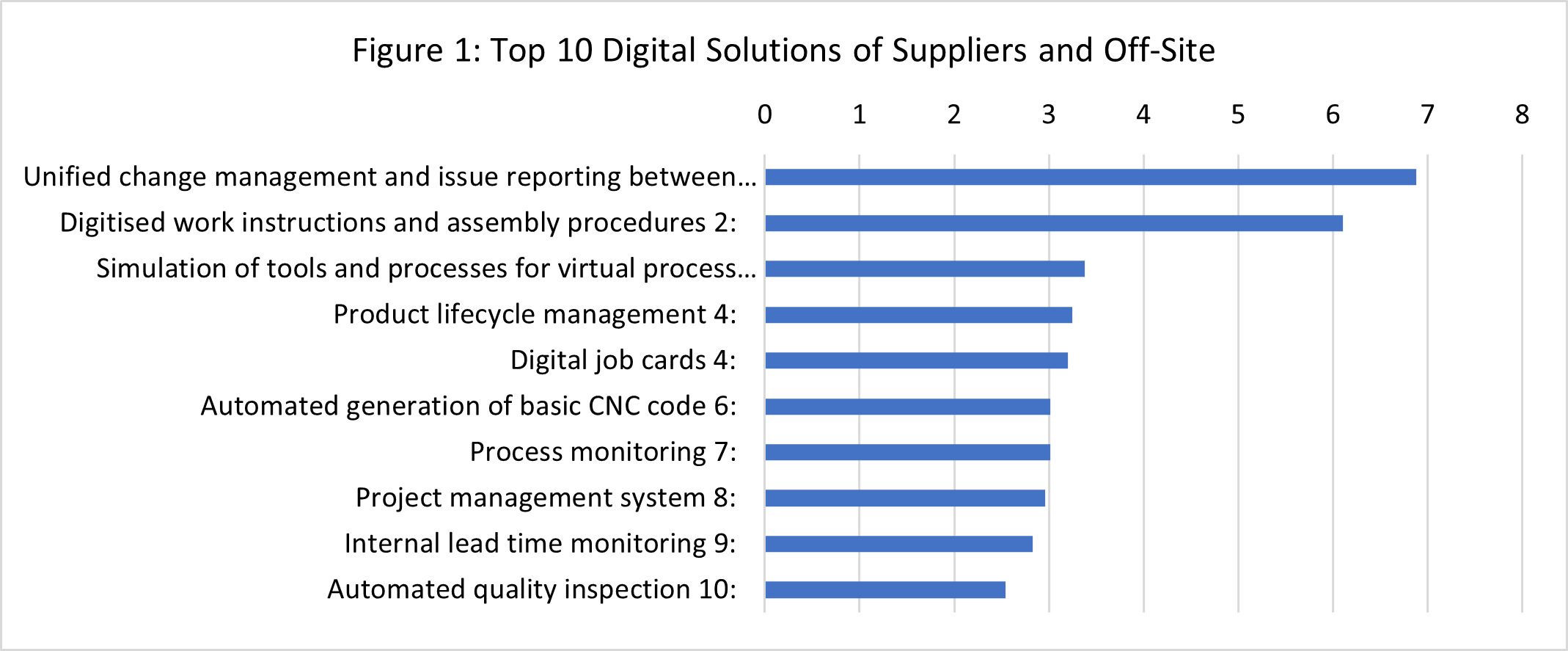

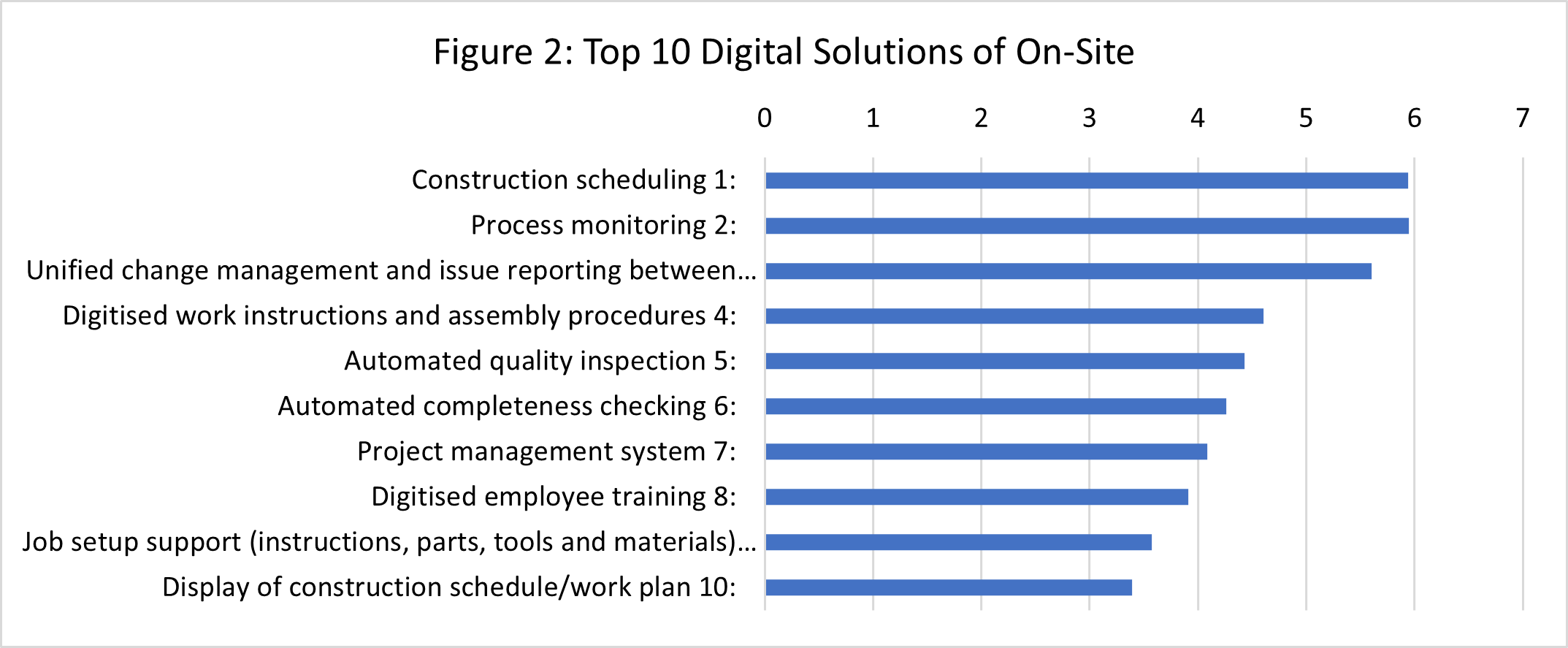

These workshops helped the research team to identify the top ten priority digital solutions required by suppliers and off-site construction SMEs (which can be seen in Figure 1), and the top ten priority digital solutions required by on-site construction SMEs (which are identified as presented in Figure 2).

Interestingly but not unexpectedly, those priorities differed between the different types of SME, when viewed in isolation.

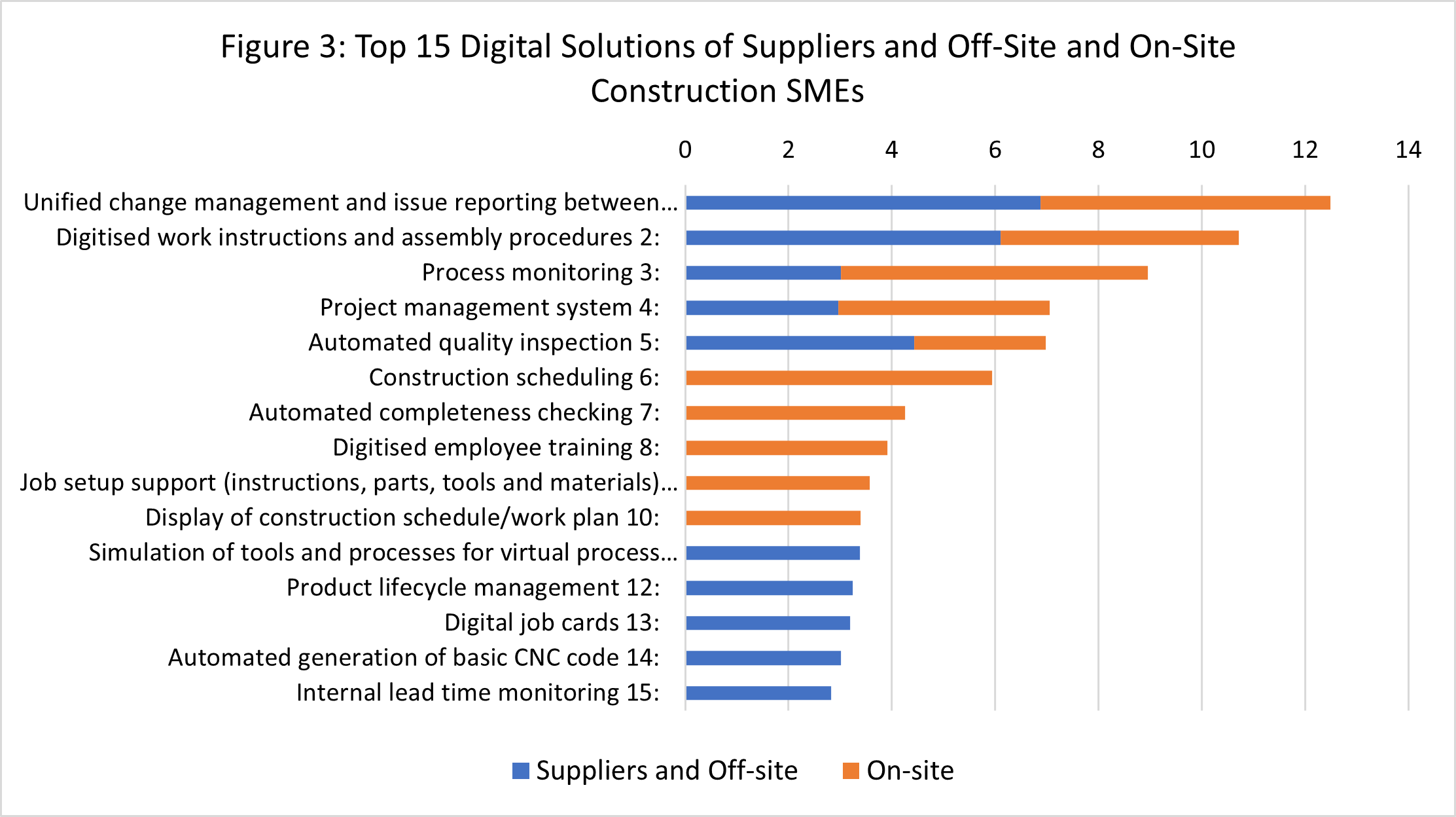

However (as Dr Yilmaz discussed with those attending) when scores were combined, the top priority digital solutions identified by both suppliers and off-site construction SMEs and on-site construction SMEs were very similar, with Unified Change/Quality Management and Issue Tracking being highest (as shown in Figure 3).

As a result, the team helped develop and deploy this solution at a modular housebuilder- one of the Digital Construction on a Shoestring partner companies.

However, during roll-out, it became apparent that the housebuilder lacked a process to help on-site building operators capture potential issues and assign them to the workforce for investigation and resolution. Thus, a tool, which allows the building crew to notify the technical team about the potential issue, was created as a solution to this problem.

Dr Yilmaz discussed that this tool has had a significant impact on three important issues:

- rectifying the quality issues quickly,

- developing the design, and

- avoiding the repetition of error.

Whilst the development and deployment of the quality management tool was for the modular housebuilder, its design - based on re-usable components - means that the tool can be used in the development of shoestring solutions for other construction SMEs.

These re-usable components can either be used to develop a quality management tool for another construction SME or be easily configured based on the requirements of other construction SMEs to develop a different shoestring solution.

This adaptability and scalability mean that a library of tools can quickly be made available to support the needs of SMEs and aid them in increasing their digital capabilities whilst keeping adoption costs low.