Submitted by Anonymous on Fri, 19/11/2021 - 09:51

A new infographic, enabled by the Construction Innovation Hub, is published today to bring to life a prototype digital twin of the Institute for Manufacturing (IfM) on the West Cambridge campus. Xiang Xie and Henry Fenby-Taylor discuss the infographic and lessons learned from the project.

The research team for the West Cambridge Digital Twin project has developed a digital twin that allows various formats of building data to function interoperably, enabling better insights and optimisation for asset managers and better value per whole life Pound.

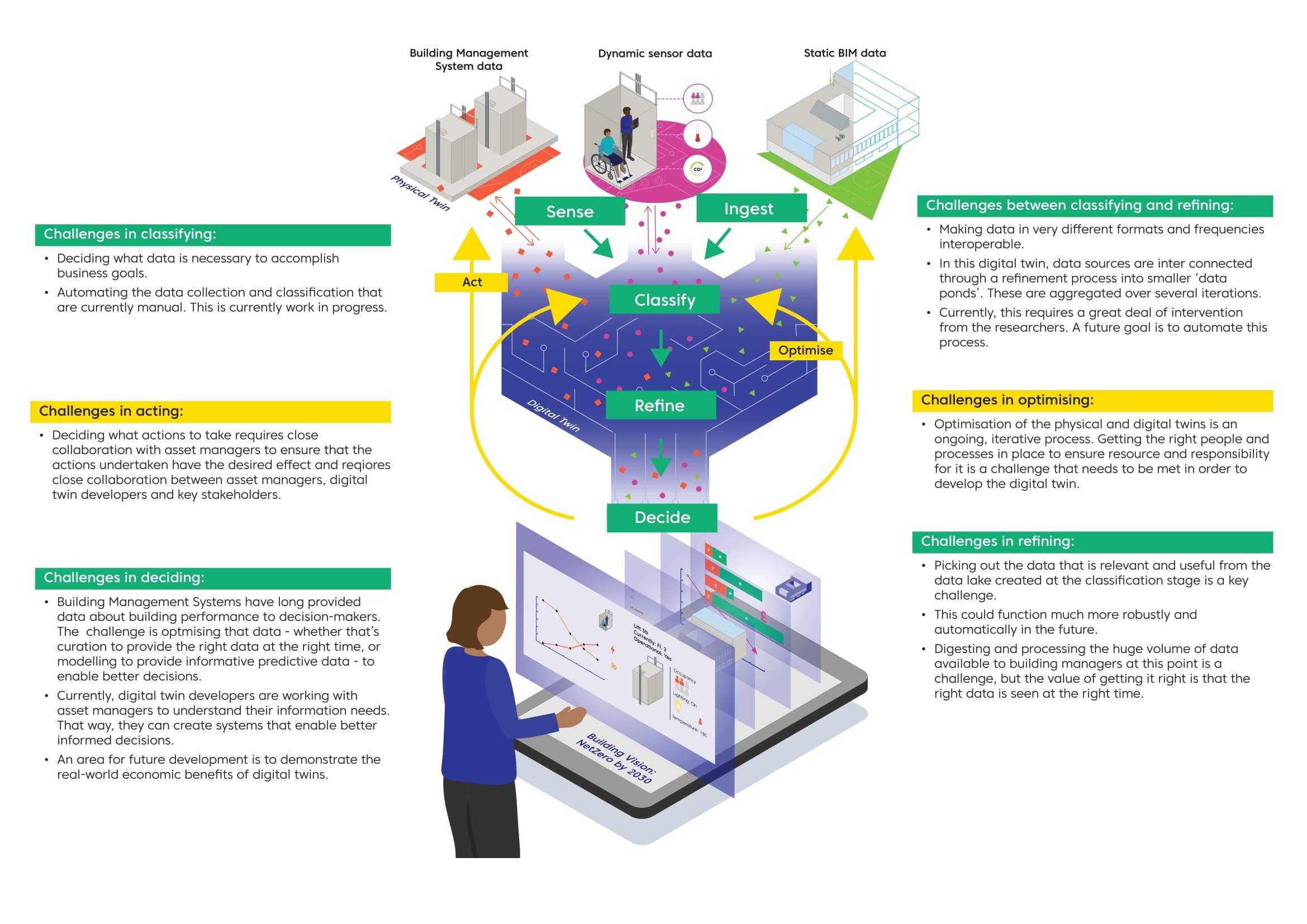

The graphic centres the asset manager as a decision maker as a vital part of this process, and illustrates that each iteration improves the classification and refinement of the data. It also highlights challenges and areas for future development, showing that digital twin development is an ongoing journey, not finite destination.

The process of drawing data from a variety of sources into a digital twin and transforming it into insights goes through an iterative cycle of:

-

Sense/Ingest - use sensor arrays to collect data, or draw on pre-existing static data, e.g. a geometric model of the building

-

Classify - label, aggregate, sort and describe data

-

Refine - select what data is useful to the decision-maker at what times and filter it into an interface designed to provide insights

-

Decide – use insights to weigh up options and decide on further actions

-

Act/Optimise - feed changes and developments to the physical and digital twins to optimise both building performance and the effectiveness of the digital twin at supporting organisational goals.

Buildings can draw data from static building models, quasi-dynamic building management systems and smart sensors, all with different data types, frequencies and formats. This means that a significant amount of time and resources are needed to manually search, query, verify and analyse building data that is scattered across different databases, and this process can lead to errors.

The aim of the West Cambridge Digital Twin research facility project is to integrate data from these various sources and automate the classification and refinement for easier, more timely decision-making. In their case study, the team has created a digital twin based on a common data environment (CDE) that is able to integrate data from a variety of sources. The Industry Foundation Classes (IFC) schema is used to capture the building geometry information, categorising building zones and the components they contain. Meanwhile, a domain vocabulary and taxonomy describe how the components function together as a system to provide building services.

The key to achieving this aim was understanding the need behind the building management processes already in place. This meant using the expertise and experience of the building manager to inform the design of a digital twin that was useful and usable within those processes. This points to digital twin development as a socio-technical project, involving culture change, collaboration and alignment with strategic aims, as well as technical problem solving.

In the future, the team wants to develop twins that can enhance the environmental and economic performance of buildings. Further research is also needed to improve the automation at the Classify and Refine stages so they continue to get better at recognising what information is needed to achieve organisational goals.

You can read more from the West Cambridge Digital Twin project by visiting their research profile.

This research forms part of the Centre for Digital Built Britain’s (CDBB) work at the University of Cambridge. It was enabled by the Construction Innovation Hub, of which CDBB is a core partner, and funded by UK Research and Innovation (UKRI) through the Industrial Strategy Challenge Fund (ISCF).

To join the conversation with others who are on their own digital twin journeys, join the Digital Twin Hub.