Submitted by Anonymous on Mon, 12/09/2022 - 11:26

Digitalisation can seem beyond the financial reach of many small- and medium-sized companies (SMEs). Barriers to engaging with digital tools and technologies include high entry and operating costs and complexity. A collaboration between academia and industry, Digital Construction on a Shoestring set out to co-deliver benefits for SMEs' digital capacity using simple, proven, low-cost digital solutions.

The Shoestring programme was designed to increase sector awareness of easy-to-access digital solutions that smaller companies can develop and apply to improve processes and drive increased productivity and profitability. This project took an approach already under development within the manufacturing sector and applied it to construction.

The big picture

The construction sector has been slow to adopt digital process and technology innovations compared to some other sectors, such as aerospace and manufacturing. The past 10 years have seen a drive for digitalisation in this sector with government, industry and industry bodies working together to support change. Aligned to the Construction Sector Deal, the Construction Innovation Hub (The Hub) was established to foster collaboration between government, academia, industry and partners across the Transforming Construction Challenge. Tasked with transforming how buildings and infrastructure are procured, designed, delivered and operated, The Hub addressed four themes – value, manufacturing, assurance and digital. The central quest was to identify innovations that support construction to deliver market-ready products and processes to shape the future built environment, ensuring safety, quality and value.

Digital Construction on a Shoestring has applied The Hub's quest to smaller enterprises, inviting SMEs and other construction organisations to work with academic experts from the University of Cambridge Institute for Manufacturing, Centre for Digital Built Britain and Centre for Smart Infrastructure and Construction, to identify specific digital solution priorities aligned with organisational objectives. What practical pathways could we identify for organisations to develop and deploy simple, low-cost digital solutions?

The case for action

Large construction companies often have IT departments and information groups that can lead and support transition to digitalisation. SMEs rarely enjoy the same resource. Digitalisation can be an expensive financial investment, and the end results are not always as expected. The Shoestring approach helps smaller companies with some digital capabilities, or a technical enthusiast keen to learn, to get started using digital tools and solutions, and increase their capabilities incrementally.

The project

The Shoestring Approach emerged from a University of Cambridge Institute for Manufacturing (IfM) project funded by the EPSRC, Digital Manufacturing on a Shoestring. That project focused on co-developing digital solutions for SME manufacturing companies. Workshops with companies identified 59 solutions and 15 shared priorities, compiled together in the Shoestring Digital Manufacturing Solutions catalogue. This is significant: deploying digital solutions at scale across many SMEs keeps costs affordable to all stakeholders. The collaborative approach encourages SMEs to develop and increase their digital capabilities based on immediate needs, rather than attempting comprehensive digitalisation. Recommending inexpensive off-the-shelf technology, Shoestring tackles cost and complexity barriers.

Hallmarks of the Shoestring Approach include:

- supporting SMEs to implement low-cost digital solutions to help improve productivity;

- providing solutions that are pragmatic, accessible, useful and based on low-cost components;

- accounting for regulations, safety and security;

- engaging creativity of students, IT and start-up communities (including through hackathons); and

- creating digital solutions that can be repeated, reused, and integrated

The process begins with a Requirements workshop with representatives from a collection of companies, to identify needs and priorities for the group. Workshop data is used to generate a shared priority list, with reference to the different stakeholders (in the case of construction: suppliers, off-site and on-site companies). Researchers then recruit stakeholder partners for case studies, supporting them to develop appropriate digital solutions for a sector-specific priority and mapping out the systems that will enable other similar SMEs to implement comparable solutions.

Digital Construction on a Shoestring targeted the practical deployment of digital solutions within the construction industry. Researchers worked with SMEs in the construction supply chain (manufacturers, architects, building contractors), as well as in off-site and onsite construction.

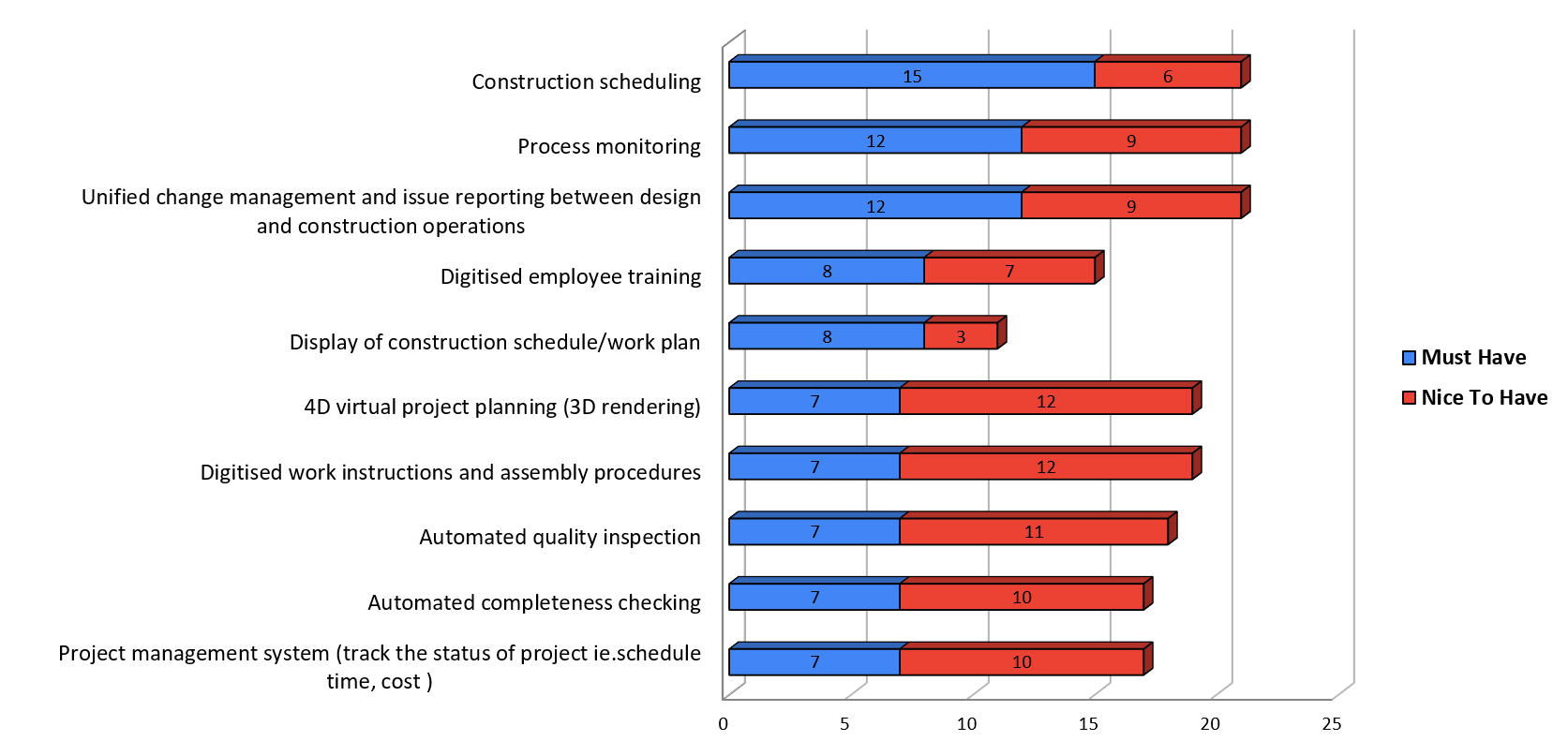

Working with SME partners in construction, the Shoestring research has generated new low-cost solutions and is compiling these into a Shoestring Digital Construction solutions catalogue. Solutions include job-tracking in a supply company (using bar code scanners and a Raspberry Pi), issue-tracking for a modular house-builder to log and learn from challenges occurring during onsite works, and inventory-tracking to support an SME working with sustainably-sourced construction materials. The ultimate goal is to create an interactive platform SMEs can use to develop and implement their own low-cost digital solutions. Learning from each of the test cases is fed back into the solutions available for others to deploy.

Image: Shoestring Digital Construction Top Ten solutions

The Shoestring team

Lead: Professor Duncan McFarlane, Professor of Industrial Informational Engineering and Head, Distributed Information & Automation Laboratory: dcm@eng.cam.ac.uk

Liz Salter Industrial Associate Institute for Manufacturing: es513@cam.ac.uk

Dr Greg Hawkridge, Research Associate at the Institute for Manufacturing: gth24@cam.ac.uk

Jan Kaiser, Research Student: jk823@cam.ac.uk

“Digital Construction on a Shoestring is a low-cost and low-risk approach which helps SMEs in the construction industry to develop simple and affordable digital solutions and to provide practical deployment of these solutions.” Jan Kaiser, Research Student, Digital Construction on a Shoestring

Engage

To learn more about the Shoestring Approach, see www.digitalshoestring.net

For an account of the Digital Shoestring for Construction project, findings and benefits, visit the CDBB project page for Digital Shoestring