Submitted by Anonymous on Mon, 22/11/2021 - 11:37

When we travel by train, we expect that we will arrive at our destination safely and on time. Safety and performance of their service network is therefore a key priority for Network Rail. Our latest video in the Digital Twin Journeys series tells the story of how researchers have inherited two intensively instrumented bridges and are transforming that high volume and velocity of data into a digital twin showing the wear and pressures on the bridges, as well as other information that can help the asset owners predict when maintenance will be required and meet their key priorities.

Remote monitoring has several benefits over using human inspectors alone. Sensors reduce the subjectivity of monitoring. Factors such as light levels, weather and variations in alertness can change the subjective assessments made by human inspectors. They may also be able to identify issues arising before visual inspection can detect them by monitoring the stresses on the bridge. A human inspector will still be sent to site to follow up on what the remote sensing has indicated, and engineers will of course still need to perform maintenance. However, remote monitoring allows the asset owners to be smarter about how these human resources are deployed.

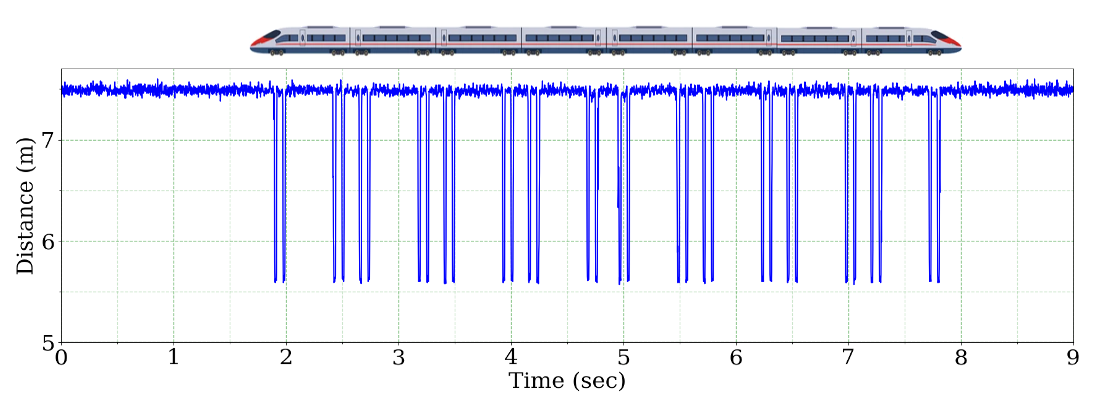

One important insight for Network Rail is based on more accurate data about the loads the bridges are experiencing, and the research team have developed a combination of sensors to make a Bridge Weigh-In-Motion (B-WIM) Technology. As shown in the video, a combination of tilt sensors, bridge deformation and axle location sensors to calculate the weight of passing trains. As the accuracy of weight prediction data is impacted by changes to ambient humidity and temperature, sensors were added that detect these factors as well. Accelerometers were added to calculate rotational restraints at the boundary conditions to improve the accuracy of weight predictions and cameras were installed so that passing trains can be categorised by analysing the video footage.

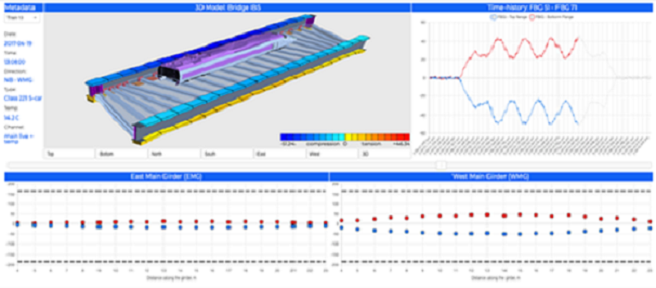

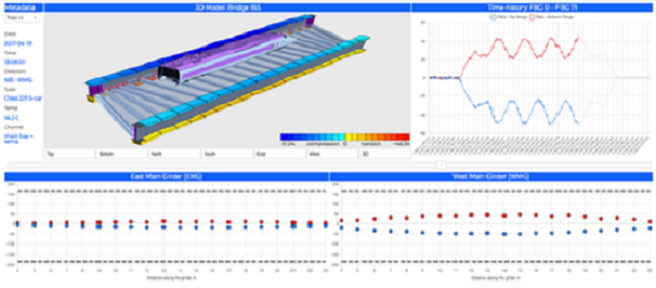

The digital twin of the Staffordshire Bridges centres on a physics-based model for conducting structural analysis and load-carrying capacity assessments. The site-specific information, such as realistic loading conditions obtained by the sensors, will be fed into the physics-based model to simulate the real structure and provide the outputs of interest. A digital twin replica of the structure will be able to provide bridge engineers with any parameter of interest anywhere on the structure, including in non-instrumented locations.

All of the sensors on these bridges produce a high volume of data at a high velocity. Without data curation, we could easily be overwhelmed by the volume of data they produce, but the research team is learning to narrow down to managing the right data in ways that provide the right insights at the right time. Working with Network Rail, this project will demonstrate the use of real-time data analytics integrated with digital twins to provide useful information to support engineers and asset managers to schedule proactive maintenance programmes and optimise future designs, increasing safety and reliability across their whole portfolio of assets.

You can read more from the Staffordshire Bridges project by visiting their research profile.

This research forms part of the Centre for Digital Built Britain’s (CDBB) work at the University of Cambridge. It was enabled by the Construction Innovation Hub, of which CDBB is a core partner, and funded by UK Research and Innovation (UKRI) through the Industrial Strategy Challenge Fund (ISCF).

To join the conversation with others who are on their own digital twin journeys, join the Digital Twin Hub.