Submitted by Anonymous on Tue, 04/10/2022 - 14:00

Development at the University of Cambridge’s West Cambridge campus offered an opportunity to demonstrate and address challenges associated with the production of a National Digital Twin (NDT). An ecosystem of connected digital twins, the NDT exists to share infrastructure and built environment data securely and so support better economic and societal outcomes. Greater data sharing could release an additional £7 billion per year of benefits across the UK infrastructure sectors [Deloitte 2017]. The NDT is a UK national resource, providing a bird’s eye view of a building, town, city or region to better understand and operate infrastructure systems and plan and predict associated services to improve quality of life.

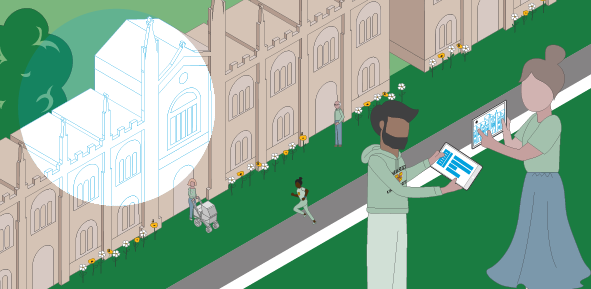

The West Cambridge Digital Twin Research Facility has implemented DT principles developed by CDBB’s Digital Framework Task Group (DFTG) to improve built asset management throughout the life cycle. Researchers fed findings from the West Cambridge sites back to the Task Group and the web-enabled (and now industry-led) community for early adopters of digital twins, the DT Hub. So what’s needed to realise the promise of DT for asset management and achieve a functional NDT?

Big picture

The Operation and Maintenance (O&M) phase for buildings and built assets often exceeds 50 years. Achieving smart building asset management is considered a complex and pressing issue for O&M, since the costs of operation and maintenance represent 50-70% of the total annual facility operation costs, while around 85% of the entire lifecycle costs of built assets are spent on the facility asset management. It is a challenging task, with large numbers of assets and a mass of data and documents for consideration (e.g., historical O&M records, performance records of facilities, accurate locations etc.). The combination of cost and difficulty means there is considerable appetite for appropriate data-handling systems, to integrate different kinds of data to facilitate analysis and ultimately increase efficiency.

A digital twin (DT) is a realistic digital representation of assets, processes and systems within the built environment. It provides a two-way connection between the physical world and the digital world, supporting the cyber physical strategy that is emerging worldwide. Data from the physical world informs the digital twin. The digital twin enables asset owners and operators to make better operational, maintenance, investment and planning decisions to create value, increase resilience and secure sustainability.

Despite numerous digital twin pilots among academic and industrial communities worldwide, none specifically addressed all the core aspects of an NDT as defined by the DFTG Gemini Principles, the paper guiding the NDT and the information management framework to enable it. Based on the National Infrastructure Commission’s (NIC) 2017 report ‘Data for the public good’, the nine foundational Gemini Principles – public good, value creation, insight, security, openness, quality, federation, curation, and evolution – combine government, academic and industry voices in shared definitions and values to guide NDT development to benefit all.

Challenges to address

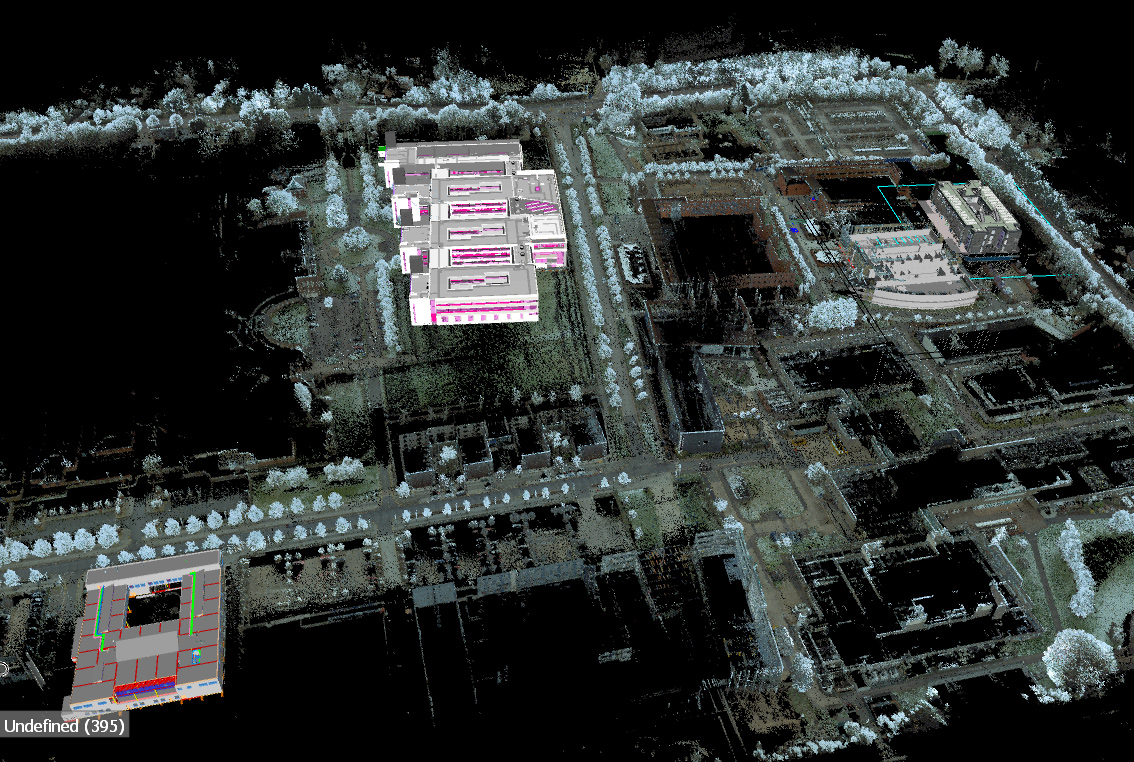

Image: Digital Twin of the West Cambridge Campus

Developing the data management framework aligned to the Gemini Principles to serve the federated digital twins that, combined, make the NDT requires significant innovation. Collecting, curating and managing rich data requires that only the required information be available to the relevant person or organisation. Transparency and security must be balanced.

Responding to the Gemini Principles, the West Cambridge Digital Twin Facility needed to be:

- flexible; created to respond to particular-and-as-yet-unknown questions

- dynamic; not a single database or even service, but created in response to particular questions being asked

- secure; much of the data and models created for and by DTs is sensitive in nature. What kind of data pipeline could mitigate security risks?

- civilised; that is, acceptable to the users on the site and the public more generally

Researchers also identified an additional challenge, linked to the desire for a dynamic tool: digital twins are more valuable if their data reflect real time, yet existing building information systems do not prioritise timeliness. What components and technologies could tackle and reduce latency?

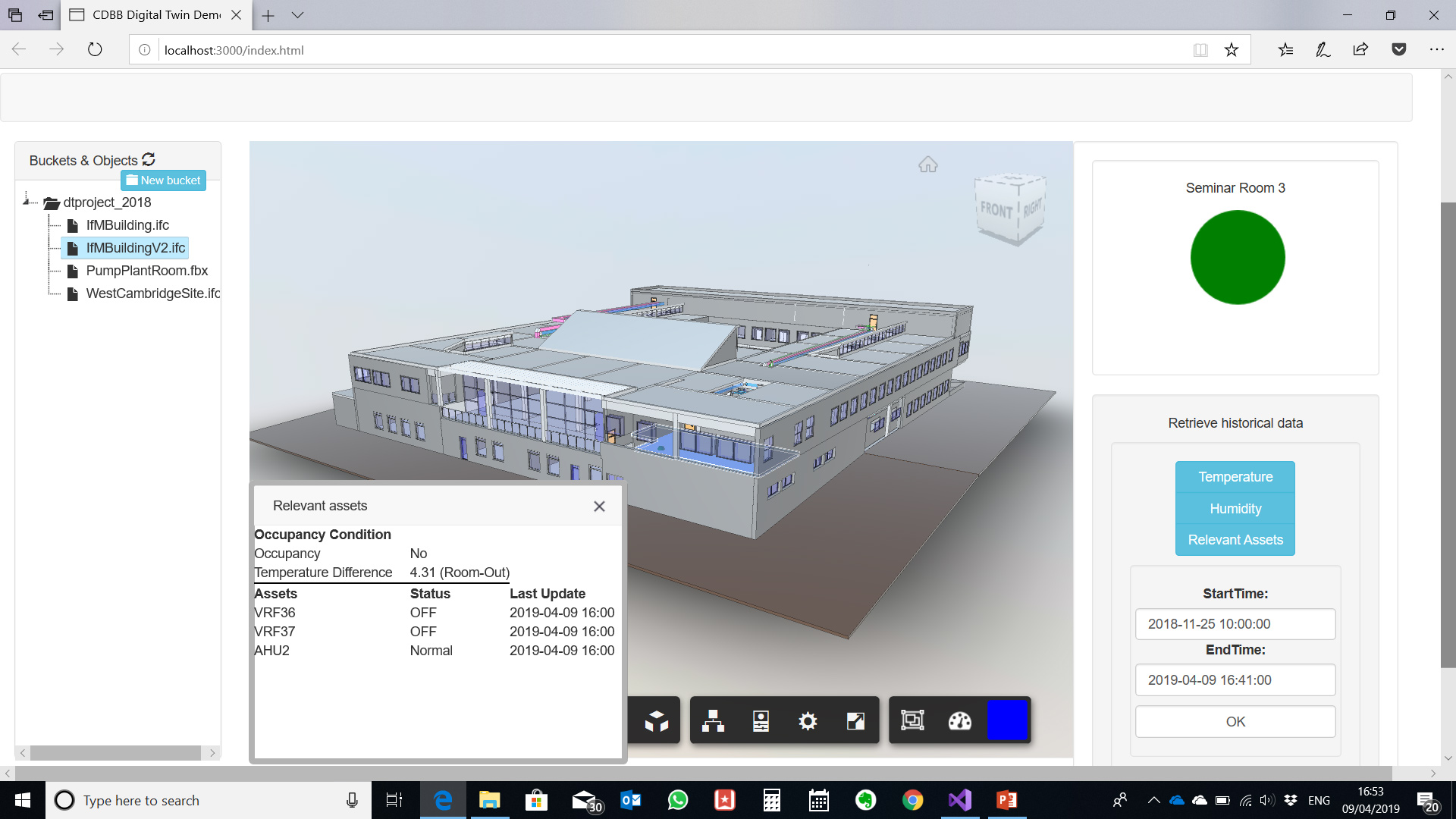

Image: Digital Twin of IfM building showing condition of seminar room and status of key HVAC equipment

The project

The West Cambridge Digital Twin Research Facility comprises digital twins of three University buildings and the surrounding environment at the campus site including the Institute for Manufacturing (IfM) in the Alan Reece Building; the Civil Engineering Building; and Department of Computer Science and Technology at the William Gates Building. The digital twins were designed to offer information useful to the Estates Division at the University of Cambridge which is responsible for a portfolio currently valued at £3 billion and featuring buildings from 800 years old to the present day.

At the outset, the researchers identified three key tasks:

- Data collection: Data need to be drawn from sensors deployed by the researchers and from built-in systems including Asset Management (AMS), Building Management (BMS) and Space Management (SMS) Systems. Sensors in the buildings and surrounding infrastructure could be used to measure energy consumption, occupancy, air quality, traffic (flow, rate and speed), and footfall.

- Data management: Key to the advancement of an NDT is development of the best possible platform and information management system to combine diverse data streams into an efficient but securely accessible and queried digital twin repository.

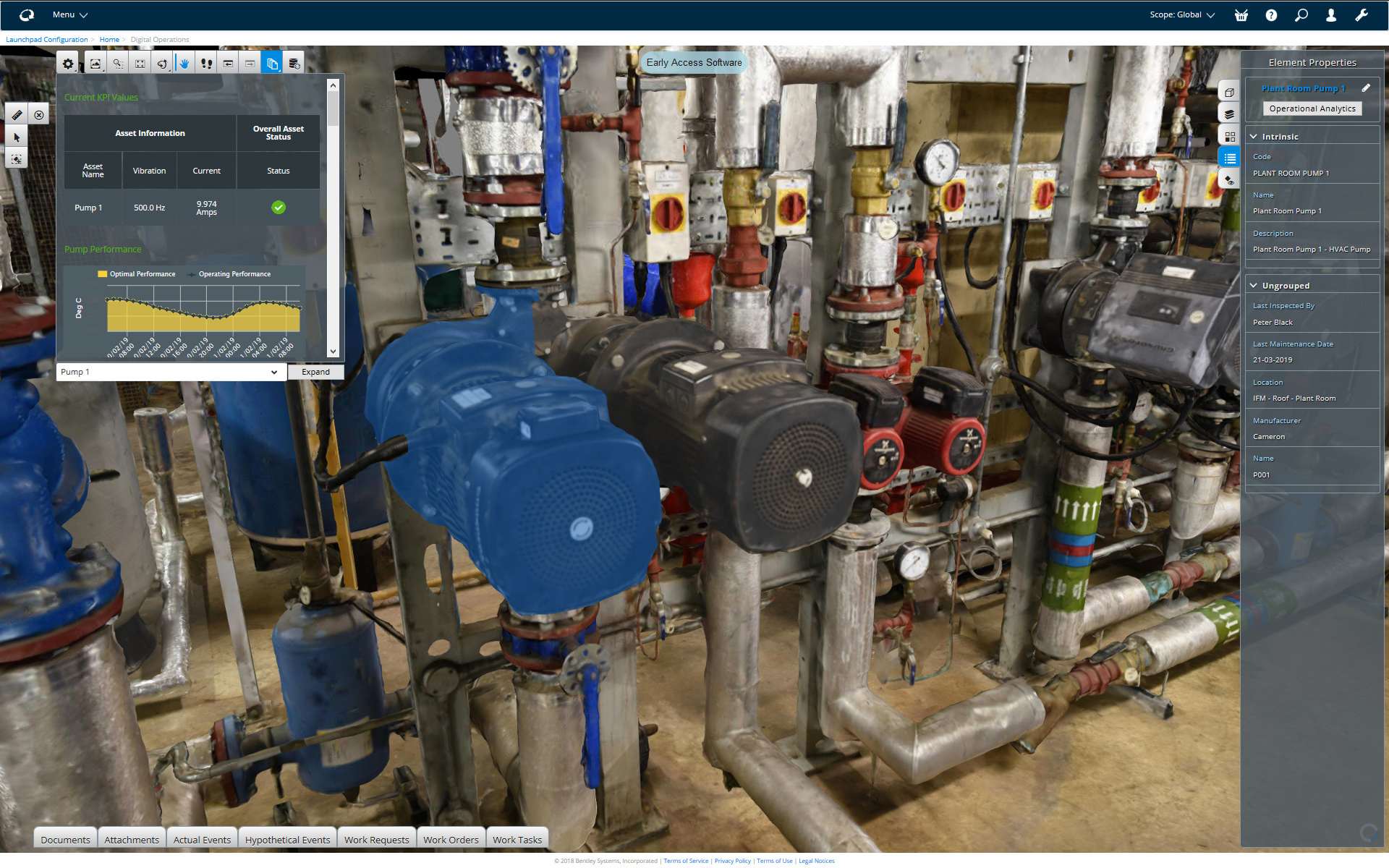

- Data for better decision-making: Data informing the digital twin is driving better asset management decision-making, improving safety and efficiency and optimising value. Algorithms have been developed to detect operational anomalies in the asset. Facility managers can be alerted to problems and access data to inform remedial action. Digital twins can also increase productivity through optimised working environments.

The closure of campus facilities for months at a time prompted by the COVID-19 pandemic necessitated adaptation to the original plans. Lab-oriented researchers instrumented their own homes with sensors, and wrangled with remote procurement processes in order to obtain and trial different components at a time when prices and availability were shifting rapidly. Despite such unanticipated obstacles, the team persevered and have delivered bespoke and cost-effective sensors, a data pipeline that focuses on capturing significant data points, algorithms to detect specific events across the target built environment, and a web-based platform that end users (facilities managers, office-based colleagues) can use to view and interpret what’s happening in their workplace.

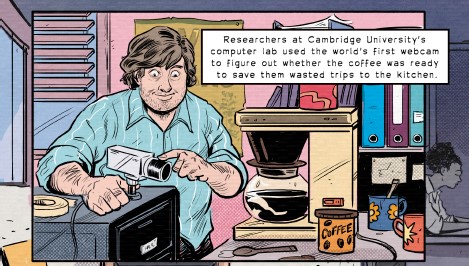

Inspired by the story behind the first webcam, laboratory researchers prototyped a playful illustration of their low-latency reporting system to ascertain not only if there was coffee in the team pot (with a weighing scale), but the likelihood of fresh coffee filling the pot anytime soon (with energy sensors on grinder and percolator). Where a regular sensor might provide updates at specified intervals, this smart set-up sends a message only when a significant event occurs (the weight of the pot changes, the grinder begins to use energy, etc.). Relying on events to trigger messages rather than logging status continuously reduces the size of data sent (and stored) by a factor of 10,000,000 or more.

Image: Digital twin of an HVAC pump showing sensor data

Meet the research team

“The approach we have taken leverages existing data schemes belonging to different domains, through a federated and scalable data model that can convey the massive data generated by the interconnected assets.”

Dr Nicola Moretti

“Our approach demonstrates how a dynamic digital twin of the built environment can unlock the value of better-informed asset management services based on IoT enabled applications.”

Dr Xiang Xie

“Although the pandemic disrupted plans, the formative digital twin presented an unexpected significant advantage: as campus re-opened, researchers could monitor the in-building environment with the spatial and temporal granularity necessary to operate safely while maximising the in-person teaching and research.”

Dr Ian Lewis

Leads: Dr Ajith Kumar Parlikad, Reader in Asset Management, Institute for Manufacturing, University of Cambridge; Dr Richard Mortier, Professor in Computing and Human-Data Interaction at the University of Cambridge Computer Lab; Dr Ian Lewis, Director of Infrastructure Investment, University of Cambridge

Team: Dr Nicola Moretti, Dr Xiang Xie, and Dr Jorge Merino, Research Associates, Institute for Manufacturing, University of Cambridge; Dr Matthew Danish, Research Associate, Department of Computer Science and Technology, University of Cambridge; Justas Brazauskas, Research Assistant; Rob Bricheno, Senior Network Systems Specialist, University Information Services, University of Cambridge; Dr Rohit Verma, Research Associate, and Vadim Safronov, a postgraduate researcher, both based in the Systems Research Group, Department of Computer Science and Technology, University of Cambridge

Engage

Visit the project page for this research here.

The Digital Twin Hub is online at: digitaltwinhub.co.uk.